Accurate estimates are the backbone of any successful automotive business. They ensure fair pricing for customers while guaranteeing profitability for the shop. On the other hand, inaccurate estimates can frustrate customers and lead to significant losses.

Let’s examine the top five areas where you may be losing money on estimates and how to address them proactively to avoid problems.

But before we dive in, try our ATI Estimate Scrubber to improve the accuracy of your estimation process, ensure compliance, and boost profitability. With advanced features, a user-friendly design, and continuous updates, it’s the best way to protect your bottom line and remain competitive in the collision repair industry.

#1. Underestimating Labor Costs

Labor costs are a common source of inaccurate estimates. Despite your best efforts, some jobs cost more time and money than you plan, negatively impacting your bottom line.

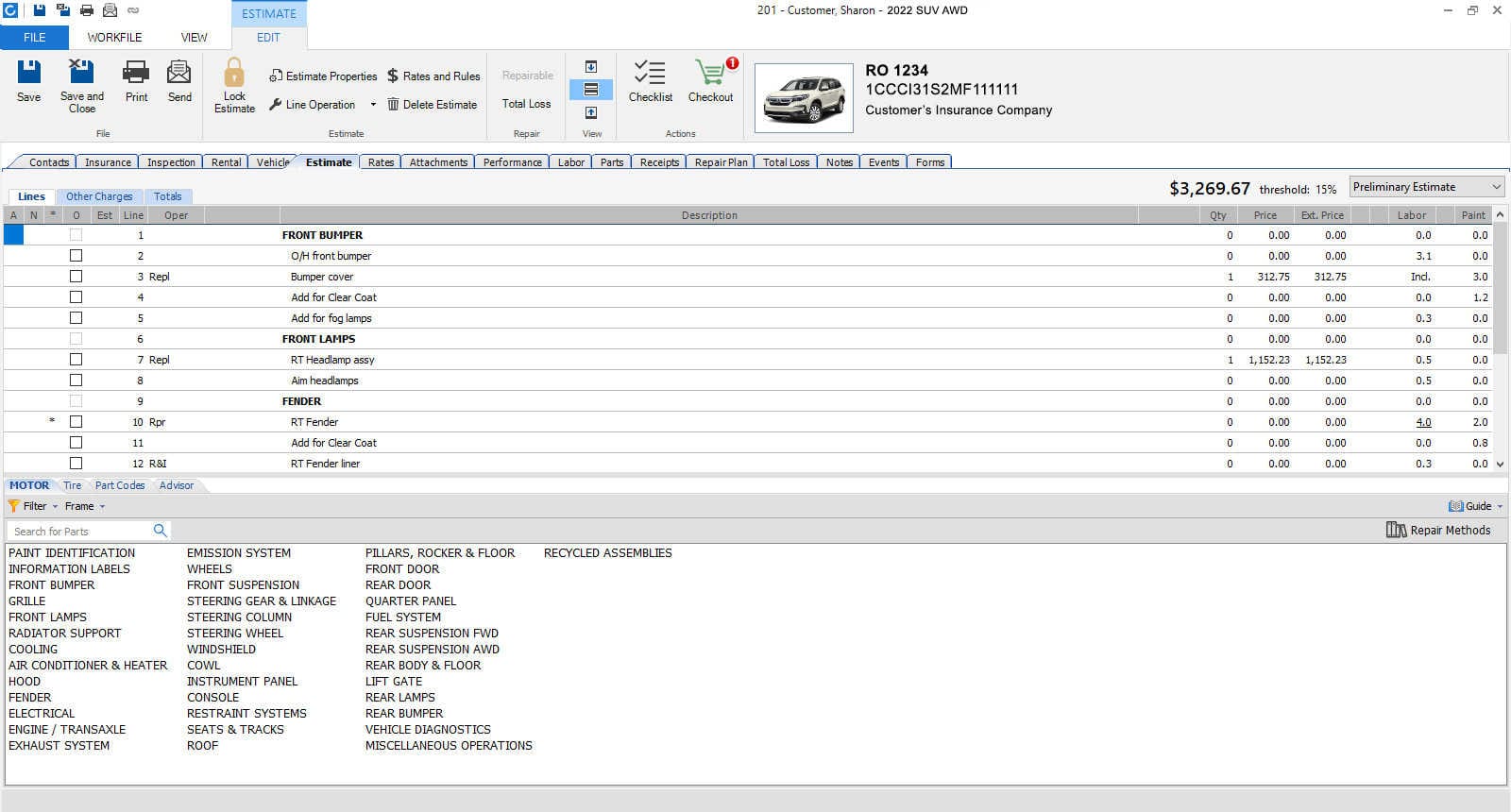

Many shops turn to automotive labor time guides to create accurate estimates. These industry standard measurements specify the time required to complete common repairs or maintenance tasks. The digital version of these guides makes it faster than ever to determine how much time you should build into your estimates.

However, the best labor time guides won’t help with inefficient technicians or incomplete estimates. So, it’s essential to ensure technicians are well-trained and up to date with their latest repair techniques. Equally crucial is ensuring estimators take the time to include everything necessary in an estimate to complete the job.

How much money are you leaving on the table? Find out with ATI’s Estimate Scrubber Tool designed to transform the estimation process for collision shop owner clients, ensuring greater accuracy, compliance, and profitability in a fiercely competitive industry. Fill out the form to download!

#2. Ignoring Hidden Costs

Hidden costs, such as administrative overhead, shop supplies, and disposal fees, can add up and eat into your bottom line if not included in the estimate.

Some examples of hidden costs include:

- The time it takes to remove damaged parts by cutting or pulling to gain access

- Any adhesives, body filler, or glaze putty used during a repair

- The time it takes to fabricate or install reinforcements or inserts

- Coolant, transmission, or power steering fluids

- The time it takes to clean up broken glass when replacing a windshield

CCC ONE helps create more accurate estimates but doesn’t always include every product or service you might use in a repair. Source: Capterra

Popular estimating software, like CCC ONE or Mitchell, doesn’t always include every miscellaneous cost. So, it’s critical to regularly review all potential hidden costs and ensure they factor into your estimates. After assessing these costs, add them to your estimating procedures to ensure they appear consistently across jobs.

You may need to defend these costs when submitting claims to insurance companies. So, document these costs in your estimates and be prepared to respond to any inquiries from customers or insurance adjusters. Emphasize that you’re being upfront and transparent rather than trying to hide them by inflating other costs.

#3. Inaccurate Parts Prices

Anyone living through the COVID-19 pandemic knows just how much parts prices can fluctuate based on supply and demand. If you underestimate the cost, parts costs could eat into your bottom line. And if you overestimate, it hurts your competitiveness.

Real-time estimation software can help eliminate any disparities when pricing parts for a repair. Unlike outdated catalog pricing, these solutions use actual market prices and live inventory feeds to provide more accurate estimates. However, it’s still a good idea to audit your parts pricing to ensure everything is correct and up to date.

Supplier relationships can also play a substantial role in minimizing parts-related issues. If you have a strong relationship with a parts supplier, they may offer better prices and inform you about any upcoming changes in parts costs that could affect your business.

#4. Warranty Work Complexity

Warranty work introduces an added layer of complexity that can lead to inaccurate estimates and a potential hit to your bottom line.

Most consumers visit dealerships for warranty work but legally can go anywhere. However, if you choose to accept warranty work, keep in mind there are stringent OEM stipulations. For example, certain common steps in a repair may not be fully covered under warranty, so you should exclude them in estimates or be clear that they are not covered.

When conducting warranty work, it’s essential to obtain a pre-authorization for repairs covered under the warranty and then keep an accurate record of the repairs and associated costs to avoid any surprises. Finally, you should ensure timely submission of claims for reimbursement to avoid unnecessary carrying costs.

#5. Failing to Negotiate Effectively

The most accurate claim itemizing every minute or labor and part used in a repair doesn’t do you any good if an insurance adjuster immediately denies the claim.

The key to effective negotiation is telling a story. Photos can help others see what the estimator sees when assessing a job and serve as documentation to prove the extent of any damage to the customer and insurance company. Meanwhile, itemized estimates help tell a story much better than clumping items together with seemingly inflated costs.

Ultimately, estimates are a communication tool that shops use to bridge the gap between their staff, customers, and insurance companies. Never assume that any costs are set in stone, but on the other hand, be prepared to defend any higher-than-standard labor costs or use of parts that may not produce the cheapest possible estimate.

Beyond the Estimate

Accurate estimates are just one part of increasing your shop’s revenue and profitability.

The other half of the equation is effectively managing costs. For example, consider optimizing your inventory management to avoid overstocking or understocking parts. You might also negotiate with suppliers to obtain better pricing and improve margins.

You may also consider investing in more efficient equipment to reduce utility costs or improve productivity. For instance, a car lift can help improve maintenance efficiency and employee satisfaction. You might also invest in preventative maintenance to prevent breakdowns that lead to downtime or other issues.

The Bottom Line

Accurate estimates protect your bottom line and enhance customer satisfaction and trust, leading to long-term success.

By focusing on these five areas, shop owners can significantly improve estimate accuracy and ensure profitability. Regular oversight, continuous training, and leveraging technology are essential strategies to mitigate losses and sustainably grow your business.

If you’re looking for more ways to improve your shops, attend one of our virtual or in-person workshops. They cover everything from digital marketing to retirement planning.